Sphere's Nixie Tube Page specifies that the IN-14 tubes require a 170-180VDC power supply and a 33kOhm resistor in series (before the anode). Most AC to DC power supplies provide between 3.3VDC to 15-20VDC. I also want to have 5VDC for logic circuits. For the first nixie clock (Nixie 1.0), I purchased a boost converter kit, something like

this one. For me, it was a "black box" when I soldered the components on, but I knew I needed to figure out a bit more about how it works if I intended on making my own from scratch.

I manually copied the circuit diagram into Eagle Cadsoft (you can get a limited version for free which should work great for this project from

here). Below is a picture of the circuit diagram I drew up. If you need help with using Eagle (...and you probably will because it is not intuitive), take a look at some youtube videos. There are comprehensive tutorials out there... that's the way I learned how to use it.

So, this schematic looks daunting, and to tell you the truth, I'm not completely certain what every part does, but I will try my best to explain what I do know. Some of my information came from this

helpful website.

I have +9VDC coming in up top. The C1 capacitor is there to smooth out the DC input in case there is any ripple. This may not be necessary, but it can't hurt. A point of warning, make sure that all of the capacitors are rated for the appropriate voltage.

The inductor (L1) is the business end of things and is hooked up at one end directly to the 9VDC and the other to a miriad of other components. The purpose of the other components is to switch on and off the flow of current in order to maintain a high potential (160-200VDC). After the diode (D1), we have 160-200VDC. So what are all of the other components?

The C3 and C4 capacitors are high-voltage capacitors which are there to buffer the output voltage. The integrated circuit (IC) is a 555 timer. The 555 timer is there to rapidly switch the transistor (Q1) on and off. When the transistor is closed (passes current), the inducted current goes to ground. Once switched open, the current is forced to pass through the diode. If this process is repeated at a rate which is faster than the decay time of the current running through the inductor, you get a potential build-up passed the diode. I will talk a bit more about how the 555 timer works in general later, but right now you have to believe me that many of the remaining components are just there to ensure the switching is rapid.

Lastly, the voltage has to be regulated, or the voltage will keep rising to no end. This is done using the resistors R3, R4, and R5. R4 is adjustable, so you can adjust the final voltage. This resistor series acts as a voltage divider, allowing the transistor (T1) to begin conducting once we reach 160-200V. Once T1 conducts, the voltage is dropped, and increases the frequency of the 555 timer cycle, providing active feedback.

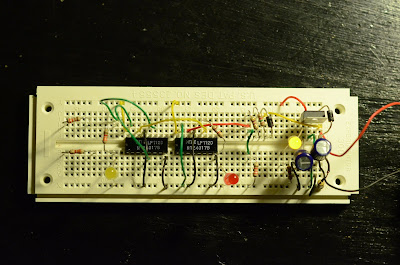

Now that I know how this works, I can begin soldering! See you next time.

share on:

facebook